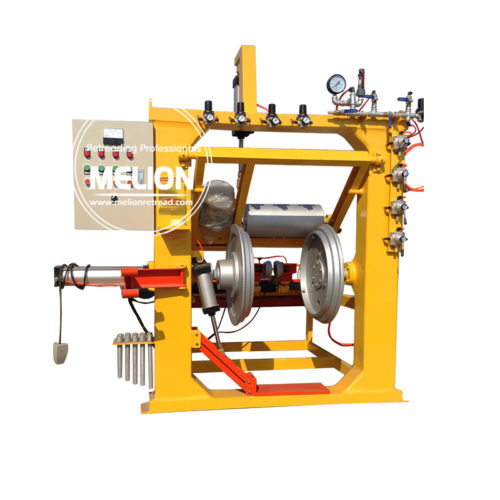

- Model: ML-FXM-F

- Wheel Chucks: 15''-16'', 20''-22.5''

- Electricity: 380V/50HZ/3Ph

- Motor Power: 16 Kw

- Dimension: 1600*1800*2100 mm

- Weight: 1650 Kg

Complete Tire Retreading Equipment: Tire Buffing Machine, Tread Building Machine, Monorail, Tire Inspection Machine, Tire Repair Machine, Extruder Machine, Extruder Gun, Envelope Spreader, Rims Mounting Machine, Rubber Cement Mixing Tank, Rubber Dust Collector etc.

-

In the Pre-cure Tire Retreading process flow, after Initial Inspection, the tire’s old tread is mechanically removed on high speed buffers.Our buffers are extremely accurate and will remove the proper amount of old rubber while turning the tire to an exact specified diameter and radius.

In the Pre-cure Tire Retreading process flow, after Initial Inspection, the tire’s old tread is mechanically removed on high speed buffers.Our buffers are extremely accurate and will remove the proper amount of old rubber while turning the tire to an exact specified diameter and radius. -

In the Pre-cure Tire Retreading System, the Tread Rubber has already been vulcanized with the new tread pattern design. The buffed tire needs a thin layer of cushion gum to be wrapped around its crown area. The Pre-cured Tread Rubber (PTR) is then applied with the building machine. This is called the MELION Retread Building Process.

In the Pre-cure Tire Retreading System, the Tread Rubber has already been vulcanized with the new tread pattern design. The buffed tire needs a thin layer of cushion gum to be wrapped around its crown area. The Pre-cured Tread Rubber (PTR) is then applied with the building machine. This is called the MELION Retread Building Process.- Model: ML-TBM-F

- Wheel Chucks: 15''-16'', 20''-22.5''

- Electricity: 380V/50HZ/3Ph

- Motor Power: 1.2 Kw

- Dimension: 1800*2100*2100 mm

- Weight: 850 Kg

-

With advances in state-of-the-art repair materials and repair methods, many of these tires can be routinely repaired and in most cases can be retreaded when the original tread is worn off. The Repair Tire Stand is where any surface injury is treated using effective material and tools for grinding and patching.

With advances in state-of-the-art repair materials and repair methods, many of these tires can be routinely repaired and in most cases can be retreaded when the original tread is worn off. The Repair Tire Stand is where any surface injury is treated using effective material and tools for grinding and patching.- Model: ML-XTJ-M

- Air Supply: 0.65 Mpa

- Electricity: 380V/50HZ/3Ph

- Motor Power: 180 w

- Dimension: 1200*1000*1500 mm

- Weight: 100 Kg

-

Even in small injuries it is critical that the injury is cleaned and filled. If this is not done, severe rust, separation and steel cable looseness could take tire out of service. The injury should be inspected, and then cleaned out with a carbide cutter. After cementing the injury, a vulcanizing rubber stem should be applied to “fill” the injury. This would create a permanent repair that maximizes tyre life.

Even in small injuries it is critical that the injury is cleaned and filled. If this is not done, severe rust, separation and steel cable looseness could take tire out of service. The injury should be inspected, and then cleaned out with a carbide cutter. After cementing the injury, a vulcanizing rubber stem should be applied to “fill” the injury. This would create a permanent repair that maximizes tyre life.- Model: ML-EXT-M

- Output Capacity: 18kg/hr

- Electricity: 380V/50HZ/3Ph

- Motor Power: 1.5 Kw

- Dimension: 1000*500*900 mm

- Weight: 80 Kg

-

Engineered with explosion-proof motor, MELION's Rubber Cement Mixing Tank stir industrial solvent and rubber materials evently to guarantee the procedure of cement spraying and brushing.

Engineered with explosion-proof motor, MELION's Rubber Cement Mixing Tank stir industrial solvent and rubber materials evently to guarantee the procedure of cement spraying and brushing.- Model: ML-JBJ-FB

- Capacity: 60 L

- Electricity: 380V/50HZ/3Ph

- Motor Power: 1.5 Kw

- Dimension: 800*800*1500 mm

- Weight: 90 Kg

-

The built tires with new tread will be mounted with Outer Envelope and Curing Rim to prepare for next procedure of Curing.

The built tires with new tread will be mounted with Outer Envelope and Curing Rim to prepare for next procedure of Curing.- Model: ML-BFT-H

- Min. Air Supply: 0.65 Mpa

- Dimension: 1600*1500*2200 mm

- Weight: 350 Kg

-

In the Pre-cure Tire Retreading System, this machine is used to Mounting and De-mounting the Curing Rims & Flanges for Enveloped Tires.

In the Pre-cure Tire Retreading System, this machine is used to Mounting and De-mounting the Curing Rims & Flanges for Enveloped Tires.- Model: ML-CGQ-A

- Tire Sizes: 15'', 16'', 20'', 22.5''

- Air Supply: 0.6 Mpa

- Dimension: 1200*900*900 mm

- Weight: 100 Kg

-

Every single tire casing will receive a thorough inspection identifying potential defects.Using Melion multiple methods to inspect tires for defects and ensure only high quality casings to be retreaded.If repairs are needed, they are administered after inspection.

Every single tire casing will receive a thorough inspection identifying potential defects.Using Melion multiple methods to inspect tires for defects and ensure only high quality casings to be retreaded.If repairs are needed, they are administered after inspection.- Model: ML-INS-22.5

- Tire Sizes: 15'', 16'', 20'', 22.5''

- Air Supply: 0.6 Mpa

- Power: 1.5 kw

- Dimension: 1100*750*850 mm

- Weight: 200 Kg

-

Collecting rubber granules which buffed off old tread by buffing machine.

Collecting rubber granules which buffed off old tread by buffing machine.- Model: ML-SJG-S

- Power: 3 kw

- Dimension: 1600*780*2000 mm

- Weight: 220 Kg

-

After Previous Procedures of Old Tread Buffing, New Tread Building,The Enveloped Tires are then Placed in this Curing Chamber and the Pre-cured Tread Rubber (PTR) becomes adhered to the tire through a vulcanizing/curing process.

After Previous Procedures of Old Tread Buffing, New Tread Building,The Enveloped Tires are then Placed in this Curing Chamber and the Pre-cured Tread Rubber (PTR) becomes adhered to the tire through a vulcanizing/curing process.- Model: ML-LHG-1500

- Applicable to all Tire sizes from 15'' to 22.5''

- Automatic alarm, Automatic timing

- Three interlock for safety

- Optional heating: electrical(standard),thermal oil and steam heating

- Over-inflating Protection engineered

-

MELION supply complete set of tire retreading equipment with different production output from 4 to 24 tyres to meet different customers' requirement.It's available for our engineers to provide onsite equipment installation and technical training services. With MELION quality rubber materials of Precured Tread Rubber ,Rubber Strip and Cushion Gum, you are guaranteed to produce quality products of retreaded tires.

MELION supply complete set of tire retreading equipment with different production output from 4 to 24 tyres to meet different customers' requirement.It's available for our engineers to provide onsite equipment installation and technical training services. With MELION quality rubber materials of Precured Tread Rubber ,Rubber Strip and Cushion Gum, you are guaranteed to produce quality products of retreaded tires.- Curing Chamber Capacity: 4 tires, 6 tires, 8 tires, 12 tires, 16 tires, 20 tires, 24 tires etc.

- Applicable to all Tire sizes from 15'' to 22.5''

- Free installation & Training services

- Rubber Materials supplying

- Good after-sale services

-

After Previous Procedures of Old Tread Buffing, New Tread Building,The Enveloped Tires are then Placed in this Curing Chamber and the Pre-cured Tread Rubber (PTR) becomes adhered to the tire through a vulcanizing/curing process.

After Previous Procedures of Old Tread Buffing, New Tread Building,The Enveloped Tires are then Placed in this Curing Chamber and the Pre-cured Tread Rubber (PTR) becomes adhered to the tire through a vulcanizing/curing process.- Model: ML-LHG-1500

- Applicable to all Tire sizes from 15'' to 22.5''

- Automatic alarm, Automatic timing

- Three interlock for safety

- Optional heating: electrical(standard),thermal oil and steam heating

- Over-inflating Protection engineered

-

MELION supply complete set of tire retreading equipment with different production output from 4 to 24 tyres to meet different customers' requirement.It's available for our engineers to provide onsite equipment installation and technical training services. With MELION quality rubber materials of Precured Tread Rubber ,Rubber Strip and Cushion Gum, you are guaranteed to produce quality products of retreaded tires.

MELION supply complete set of tire retreading equipment with different production output from 4 to 24 tyres to meet different customers' requirement.It's available for our engineers to provide onsite equipment installation and technical training services. With MELION quality rubber materials of Precured Tread Rubber ,Rubber Strip and Cushion Gum, you are guaranteed to produce quality products of retreaded tires.- Curing Chamber Capacity: 4 tires, 6 tires, 8 tires, 12 tires, 16 tires, 20 tires, 24 tires etc.

- Applicable to all Tire sizes from 15'' to 22.5''

- Free installation & Training services

- Rubber Materials supplying

- Good after-sale services