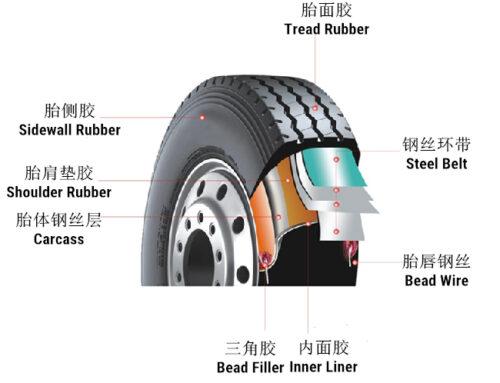

Retread, also known as “recap”, or a “remold” is a re-manufacturing process for tires that replace the tread on worn tires. Retreading is applied to casings of spent tires that have been inspected and repaired. It preserves about 90% of the material in spent tires and the material cost is about 20% compared to manufacturing a new one.

Applications

Some applications for retreaded tires are airplanes, racing cars, buses and delivery trucks. Use of retreaded tires was common historically, but as of 2008, it was seldom used for passenger vehicles, mainly due to discomfort on the road, safety issues and cheaper tire brands surfacing on the market.

Process

There are two main processes used for retreading tires, called Mold Cure and Pre Cure. Both processes start with the inspection of the tire. Some casings are repaired and some are discarded. Tires can be retreaded multiple times if the casing is in usable condition. Tires used for short delivery vehicles are retreaded more than long haul tires over the life of the tire body. Casings fit for retreading have the old tread buffed away to prepare for retreading.

Material cost for a retreaded tire is about 20% that of making a new tire. About 90% of the original tires by weight is retained in retreaded tires. A 1997 study estimates that then current generation of commercial vehicles tires to last up to 600,000 miles if they’re retreaded two to three times.

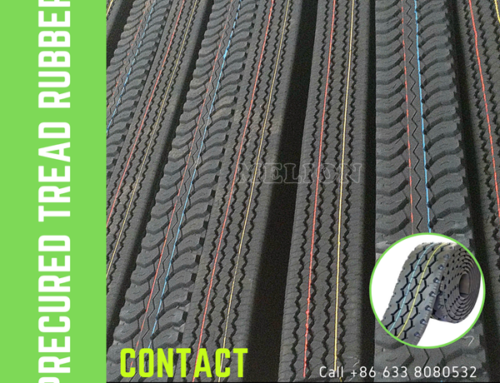

Pre-cure

Precure Retread also called “Cold” Retread. Previously prepared tread strip is applied to tire casing with cement. This method allows more flexibility in tire sizes and it is the most commonly used method, but results in a seam where the ends of the strip meet.

Mold-cure (Hot)

Raw rubber is applied to the tire casing and it is then placed in a mold where tread is formed. A dedicated mold is required for each tire size and tread design.