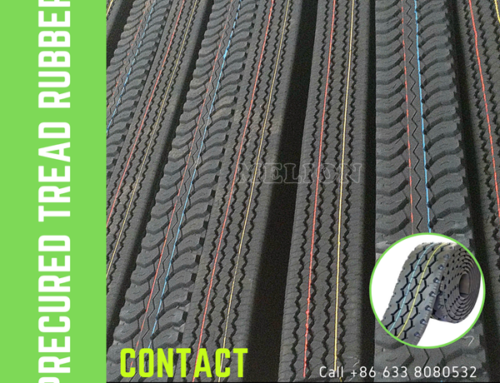

Advantages of Cold/Precured Tire Retreading Process:

Precured rubber generally gives more mileage than the conventional rubber due to richer compound, denser tread and flatter profile;

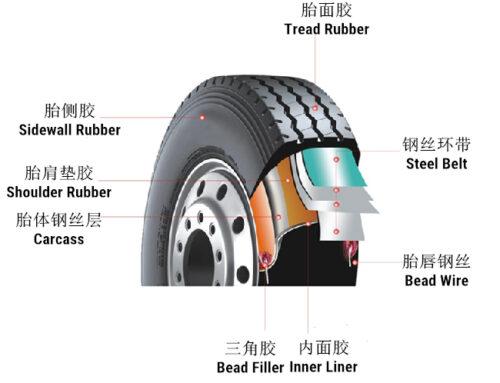

For radial tires, pre-cure retreading is the most ideal process. Radial tire, in its construction, has an inextensible belt. In the conventional retreading process the matrix (rigid mould) should have exact dimensions matching the dimensions of a built radial tire. Even a small difference in the matrix dimension affects the ultimate performance of the retreaded tire. But in the case of pre-cure retreading, radial tires are cured in a chamber and not confined to a rigid matrix or mould, hence there is no distortion.

Longer casing life because tire is retreaded in inflated normal road running condition. Thus the casing is not put under tension and over stressed as it happens inside a rigid mould. (Due to distortion of casing, the number of times a tire can be retreaded with conventional retreading is always lesser than with pre-cure retreading).

Better balancing, due to uniform thickness of tread and better buffing and building techniques.

Better traction due to flatter profile of buffing.