Retreading Is Recycling

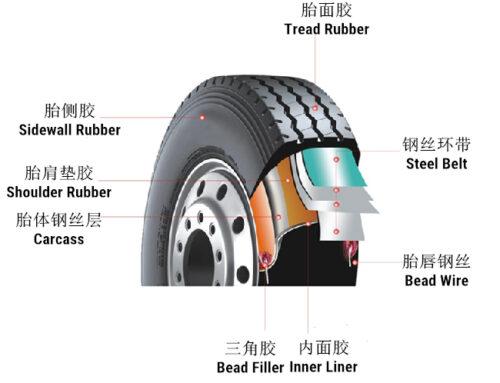

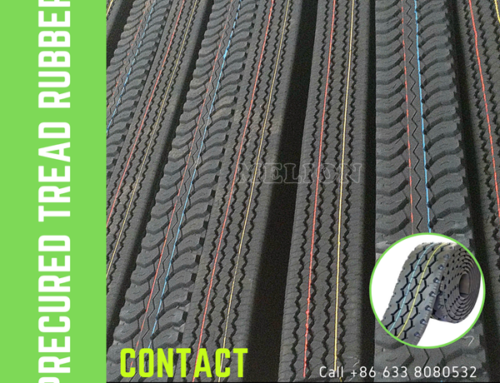

Retreading is the process whereby selected and inspected worn tyres, called ”casings”, receive a new tread. Only sound, carefully inspected tyre casings are used for retreading. The worn tread is buffed away and a new tread bonded to the tyre body in a process very similar to the manufacture of a new tyre.There are different processing techniques, but the ultimate objective is always the same-affixing a new tread through the application of heat, time and pressure.

Retreaded tyres are proven reliable

They are used by commercial airlines, military aircraft, school buses, government vehicles and emergency transport of all kinds. Trucking companies routinely depend on retreads for long-distance hauls. Retreaded tyres have been proven as reliable and durable as new tyres in laboratory tests and through years of practical experience in all the same applications where new tyres are used. In some cases, retreads have become the product of choice for certain applications where new tyres are not used by the fleet.

Retreading is an excellent way to save money

A properly constructed and maintained retreaded tyre will give comparable miles per tread depth as a new tyre. In fact, the more expensive the original new tyre, the greater the retread savings. Since many tyres can be retreaded one or more times, to discard a worn tyre without retreading is to lose most of its value. Whether you are a fleet professional, or an owner-operator, retreaded tyres are a viable economic alternative to new tyres.