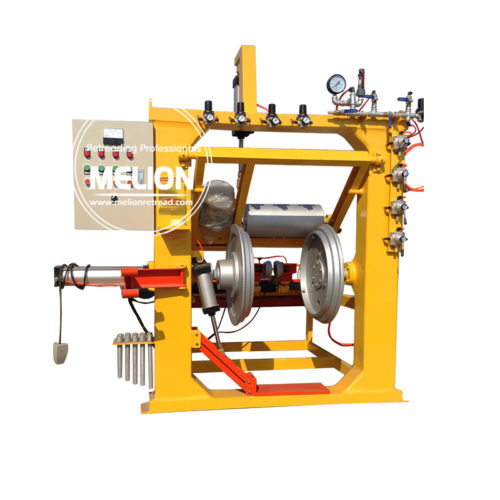

After Previous Procedures of Old Tread Buffing, New Tread Building,The Enveloped Tires are then Placed in this Curing Chamber and the Pre-cured Tread Rubber (PTR) becomes adhered to the tire through a vulcanizing/curing process.

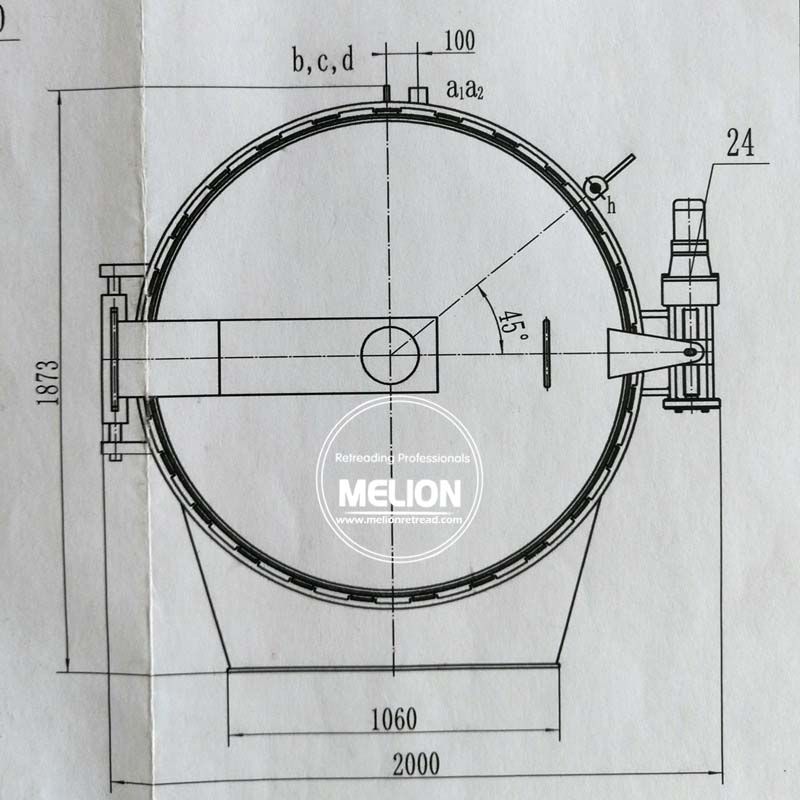

- Model: ML-LHG-1500

- Applicable to all Tire sizes from 15” to 22.5”

- Automatic alarm, Automatic timing

- Three interlock for safety

- Optional heating: electrical(standard),thermal oil

and steam heating - Over-inflating Protection engineered